These 6 Oat Flours Are Revolutionizing Beverage Formulation

February 11, 2019

Throughout our 30+ years in the oat business, we’ve seen food developers have huge success using oats to meet a wide range of needs. This success has continued with the rise in popularity of using oats in plant-based beverages.

You may have seen oat milk starting to pop up next to the soy and almond milk on grocery store shelves lately, each with a slightly different texture, flavor, and nutrition profile. Whether a developer is seeking flavor, nutrition, health benefits, synergistic functionality, processability, or texture, Grain Millers offers a wide range of functional oat flours, which can provide solutions to many formulation challenges.

OAT FLOUR IS NOT ONE-SIZE-FITS-ALL

Grain Millers’ Functional Flours, with their wide range of properties, can uniquely control important characteristics such as thickening and gelling, stabilization, mouthfeel, and dispersion in your end product. Grain Millers is known for its state-of-the-art oat manufacturing capabilities and we are using that expertise to develop oat products that are relevant to the explosive and rapidly changing beverage market.

“No one functional oat flour is one-size-fits-all, which is why Grain Millers manufactures a variety of flours using different milling techniques,” explains Roberto Serrano, Vice President of Product Development. “Each has its own functionality that accommodates various textures, flavors, sweetness, and nutrition requirements.”

From wet processing (UHT, ESL, retort, hot fill, HPP, PEF, tetra

RANGE OF OAT FLOUR MODIFICATION & FUNCTIONALITY

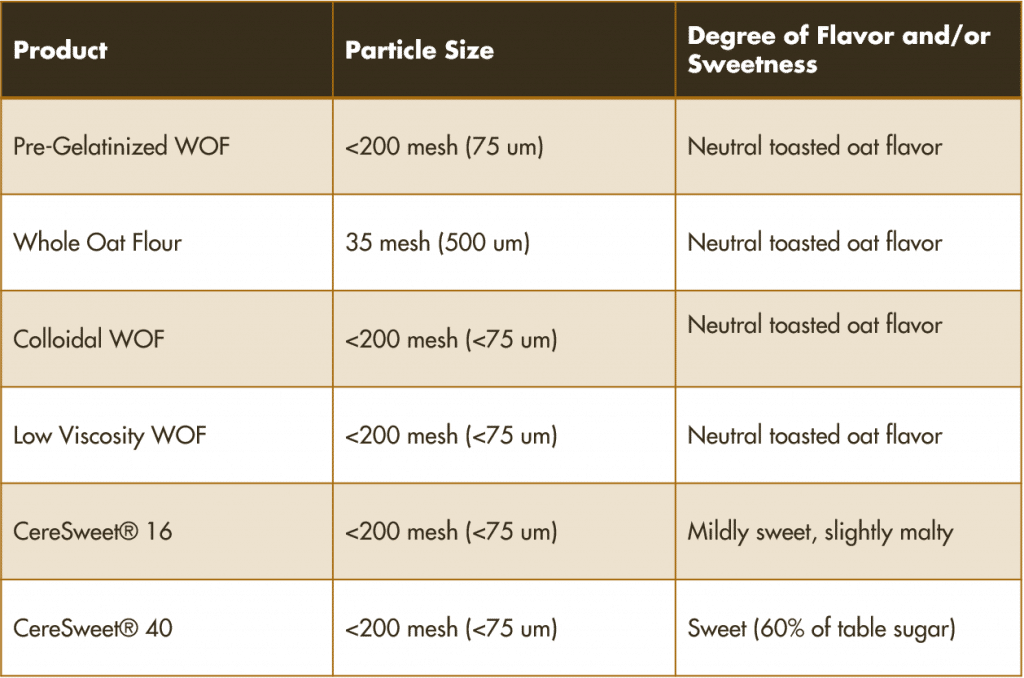

The following two charts outline the characterizations of each of Grain Millers’ Functional Oat Flours. This first chart shows the particle size in relation to the degree of flavor and/or sweetness modifications.

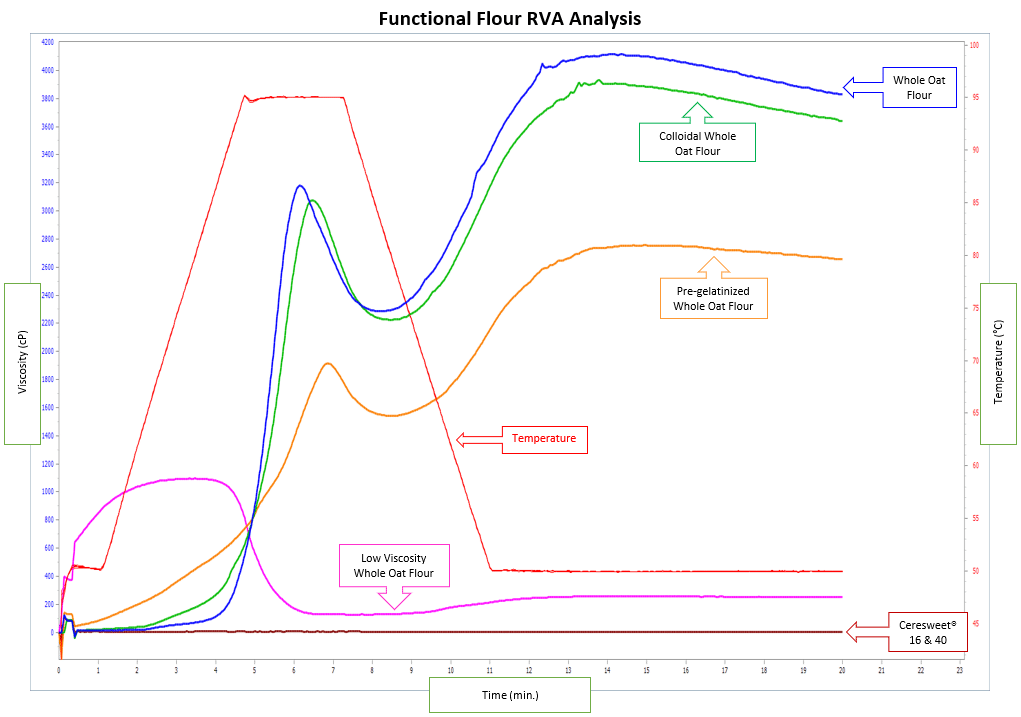

This second chart illustrates the rheological properties of the various oat flours by using the Rapid Visco Analyzer (RVA) and specifically comparing viscosity in relation to temperature and rate of hydration. This rheological comparison may assist the user in establishing the best processing conditions.

OAT FLOUR PERFORMANCE IN COMMON BEVERAGE BASES

While we have witnessed the use of these oat flours in numerous applications, the performance of each one depends on your specific processing system and desired end-product. Below is some direction on how each of these flours

- Beverages with low solids (>2%): You may be able to utilize a whole oat flour or if you would like to add pronounced “malty,” oat-flavor notes and a high degree of sweetness, CereSweet® 16 and 40 may be a great option.

- Beverages with high solids (>5%): With the goal of delivering nutrition per serving, beverages with high solids require a flour with lower viscosity, such as our Low-Viscosity Whole Oat Flour or Ceresweet® 16.

- Creamers: The struggle with creamers is that they have higher solids to improve mouthfeel, but still go through a customized high-pressure homogenization which is typical in the dairy industry. A very low viscosity flour typically does well but it depends on the system used.

- Smoothies: The textural beauty of this base is that it offers the ability to use a wider range of oat flours.

- Mixing oat bases with other ingredients: This can provide the benefit of combining the best of multiple bases with their unique consumer health benefits. The texture is driven by the process used, including the pH, flavor combinations, and synergistic ingredients (i.e. emulsifiers, stabilizers, etc.)

- Functional, nutritional, and meal replacements: Our CereSweet® 16 & 40 and Low-Viscosity Whole Oat Flour are easily digestible and designed with these applications in mind.

CLEAN LABELING AND CERTIFICATIONS

Most oat flours from Grain Millers can be labeled as Whole Oat Flour or Oat Flour and whole grain. All are

If you would like to request a sample or discuss how our functional oat flours might help with your formulation needs, we would love the opportunity to speak with you. We specialize in partnering with food and beverage developers to create unique, innovative ingredients that help you succeed.

Email us or give us a call at 541.341.6461 to get in contact with the appropriate expert.