Grain Millers Gluten-Free Oat Products – A Pioneered, Proven, Promise.

March 24, 2020

How Do Oats Become Certified Gluten-free?

Although oats are naturally gluten-free, they can become contaminated by gluten-containing grains as the supply moves from the field, to on-farm storage, to trucks and railcars and eventually through the mill. In 2008, Grain Millers began pioneering a proprietary gluten-free oat production process, giving us the ability to remove gluten-containing grains from the oat stream and offering the purest possible oat products. Thus meeting nutritional desires and dietary needs of the growing gluten-free consumer base.

In 2008, Grain Millers began pioneering a proprietary gluten-free oat production process…

After installation of our gluten-free milling system, it wasn’t as simple as notifying the industry we now had gluten-free oat products. The certification process involved multiple on-site visits and nearly 1,000 individual samples. Our gluten-free milling flow was audited from top to bottom for its ability to produce oat products that met the FDA’s standards time and time again. We completed the certification with the help of BRCGS, utilizing their Gluten-Free Management System. We continue to operate this system with same stringent checkpoints and robust sampling procedures we used to achieve our certification.

Why Gluten-Free Oats?

Gluten is a protein found in wheat, barley, rye, and crossbreeds such as triticale (a hybrid of wheat and rye). Celiac disease; a genetic autoimmune disease that limits a person’s ability to digest gluten, affects 1 in 100 people worldwide. It is estimated that another 6-7% of the population may have a sensitivity or intolerance to gluten. In an effort to regulate the food system, the FDA set a limit of 20 parts per million (ppm) for the unavoidable presence of gluten in foods that are labeled as “gluten-free.” This amount is so low that it is tolerated by most people with Celiac disease.

Gluten-Free Oats Production Process

Grain Millers’ gluten-free oats are processed in a way that effectively removes all wheat, barley, rye and hybridized grains that may possibly arrive at our facilities with the oats. Through our dedicated gluten-free cleaning process, we isolate a highly pure groat stream that is further purified and refined in our dedicated gluten-free milling system. (A groat is the nutritious grain of an oat after its outer husk has been removed. Groats are rolled into the “rolled oats” that we know and love).

Grain Millers dedicated gluten-free milling system took years to develop and perfect, and we regard it as Top Secret! Although the machinery we use in the process are important, our team of mill operators are a vital part of the process, responsible for monitoring and adjusting the equipment. Our millers have been educated about celiac disease and have been trained on both Grain Millers gluten-free milling practices and the specifics of gluten-free testing.

Grain Millers dedicated gluten-free milling system took years to develop and perfect, and we regard it as Top Secret!

Our dedicated mill operators would tell you they could not perform their duties without the help of our lab staff who are responsible for verifying all gluten-free samples meet our <10ppm gluten specification. Our lab staff performs the rigors of gluten-free testing in dedicated gluten-free clean rooms.

How Does the Gluten-Free Equipment Work?

While cleaning and purifying grain stream is simple in concept, there’s a lot that goes into deploying this technology to and repeatedly achieves the desired results. We like to think that there are equal parts art and science that go into configuring and operating grain cleaning systems. So, we don’t know whether to call our millers artists or scientists, but in reality, they are a little bit of both. We’ll just settle on calling them awesome!

Our 4-generations of oat milling experience led us to believe we could achieve <10ppm on every load of oats from any of our dedicated farmers and the installation of our gluten-free lines and their continued performance has a proven this to be true. Our record of achieving gluten-free results through processing was proven to exceed that of the Purity Protocol strategy of excluding the presence of gluten-containing grains only at the farm and transportation levels of the supply chain.

Our 4-generations of oat milling experience led us to believe we could achieve <10ppm on every load of oats from any of our dedicated farmers…

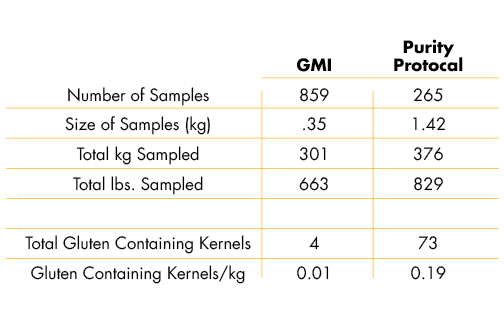

In direct cross-examination of Purity Protocol gluten-free oats and Grain Millers gluten-free oats, a 2018 study completed by the Gluten Intolerance Group of North America showed Grain Millers’ gluten-free oats in the table below. During the completion the study Grain Millers gluten-free products were analyzed using a ≈70% larger sample pool than that of the Purity Protocol gluten-free products. A copy of that study is available here for download.

Seed cleaning of grains has existed for decades if not centuries. In order for farm purity programs to be successful, harvested grain which will be used for seed in upcoming crop years, periodically requires cleaning to mitigate increased contamination levels other grains and weed seeds in subsequent crops. With our knowledge that oats are routinely purified for seed planting, we thought, “Why not then also for consumption?”

Grain Millers Oats Exceed Gluten-Free Regulations

In addition to rigorous process, we take samples of the gluten-free groat stream every 3 minutes of production to further ensure that it is pure. In order for oats to be certified gluten-free, gluten levels must be less than .002% or 20 ppm.

Our goal was never to merely meet the strict regulatory limit of 20 ppm—we wanted to see just how pure we could get our oat products! We’ve perfected our gluten-free production process to the point where most of our customers depend on us to supply oat ingredients that are less than 10 ppm–a 100% improvement in the purity level required for gluten-free labeling.

Gluten-Free Oat Production Doubled

The need for certified gluten-free oats has continued to rise. In response, we have invested in a major expansion at our oat mill in Yorkton, Saskatchewan, Canada. This expansion has more than tripled our gluten-free production capacity, giving us one of the most advanced oat mills in the world strategically located in the heart of some of the most fertile oat acreage in North America. We can depend on our local oat farmers to supply us with the best oats on the continent that we care for and mill into the highest quality gluten-free oats from Grain Millers, they are receiving much more than a standard oat-based ingredient. As with all our products, the work we do producing gluten-free products is more than processing, it’s our promise.

Other Gluten-Free Grains and Seeds

Grain Millers offers many other grains, seeds, and pulses that are naturally gluten-free. These ingredients can be great alternatives to gluten-containing grains. They do not encounter gluten throughout their process and do not require any additional processing to ensure they are gluten-free.

- Corn, corn meal, corn flour, corn grits, corn bran

- Flax, flax meal

- Brown and white long-grain rice

- Soybeans (non-GMO natto, white hilum, high protein)

- Quinoa (white, red, black, tricolor)

- Tapioca starch

- Amaranth

- Lentils (green, brown, black, split red)

- Mustard (brown, yellow)

- Pumpkin seeds

- Sunflower seeds

- Chia seeds

- Sesame seeds

In addition to being a gluten free oat supplier, Grain Millers also offers certifications such as organically certified, non-GMO, kosher, and halal.

We specialize in partnering with food and beverage developers to create unique, innovative ingredients that help you succeed. If you have questions about our gluten-free ingredients, or anything else, we’re always happy to help you.

Email us or give us a call at 800.232.6287 to get in contact with an expert.